Welcome to the Decarb Guidebook

Approach

Benchmarking

Building Codes & Design Standards

State & Local Regulations

Technologies: Load Reduction

Technologies: Dehumidification

Technologies: If you must have a gas-fired boiler

Technologies: Central Plant

Technologies: Domestic Hot Water

Technologies: Steam

Technologies: Load Shifting and Energy Storage

Technologies: Emerging Technologies

Motivation Program

Pilot Projects

How to Pay for Decarbonization

Community Discussions

Workshops

Executive Summary

Displacement ventilation (DV) allows efficient and comfortable space conditioning by strategically supplying air at lower velocities and at a temperature closer to the room setpoint. The cool supply air displaces the warmer (and contaminated) air due to buoyancy, pushing it to return registers. Traditional overhead mixing systems supply air at higher velocities and lower temperatures from ceiling diffusers, which encourage air mixing in the space. Since DV supplies air directly to the breathing zone, occupant comfort is improved and cooling requirements are reduced.

Displacement ventilation greatly decreases the amount of energy required to ventilate a space when compared to traditional overhead mixing systems. Less heating energy is needed due to lower overall air quantities and the higher temperature of the DV supply air delivered to the space (saving both cooling energy and reheat energy). Energy models from previous projects indicate a 25-35% reduction in required cooling and a 15-20% reduction in space heating energy.

DV generally does a better job of maintaining comfort under cooling conditions, due to the lower air velocities and warmer supply air temperatures. With slow cool air supply the “waterfall” effect moves the cold air to the area where the cooling load is generated (see figure below). Where heating is needed, supplemental systems are often used.

Figure 1. Temperature Distribution in Displacement Ventilation; Mazzetti presentation on LPCH

Displacement Ventilation

Technical Description

Where it’s used

Displacement ventilation (DV) has been used in Europe since the 1970s, mostly catalyzed by the energy crisis of 1978-79. In the United States, some notable facilities utilizing DV include:

- Lucile Packard Children’s Hospital at Stanford Children’s Health (Packard Children’s)

- CPMC Cathedral Hill Hospital in San Francisco

- California Theater in San Jose

- Hearst Tower in NYC

- Monterey Bay Aquarium

- San Jose State University’s Spartan Recreation and Aquatic Center

- Jess Jackson Sustainable Winery Building at UC Davis

- Terminal 2 and International Terminal’s Boarding Area A at the San Francisco International Airport

How it works

Displacement ventilation delivers tempered air near the breathing zone, which greatly increases the ventilation effectiveness (i.e. effectiveness of supply air distribution to the breathing zone, see ASHRAE 62.1). Traditional overhead mixing systems use ceiling supply and return registers, which rely on air velocity for mixing. A portion of this air never reaches the occupants, so the volume of supply air is increased to compensate. This leads to increased fan, cooling, and space heating energy as well as larger ducts.

Displacement ventilation systems also supply air at temperatures closer to the room setpoint. As air warms due to heat sources in the room, buoyancy effects cause the air to rise. Fresh and unmixed air is pooled within the breathing zone and displaces the warmed air, which is removed from the space, as shown in Figure 1 below. Only the lower 60% of the space (from the floor to approximately 6 feet above the floor) - the “breathing zone” - necessitates direct cooling.

Figure 1: Supply and return air flow in a room in a Displacement ventilation system

When designing for overhead mixing, the temperature differential between the supply air and room setpoint is typically around 20 degrees. For DV, in order to achieve acceptable levels of thermal stratification, the difference between the room setpoint and supply air temperatures is only 5-10 degrees, which improves occupant thermal comfort [Price DV Design Guide]. NOTE: Additional coordination with the architect and other trades is likely needed to accommodate the *larger diffuser areas and lower air supply (*compared to that of a conventional overhead system).

For heating days, additional heating systems must be applied, typically in the form of floor- or wall-mounted radiators or radiant panels (usually wall or ceiling mounted). However, since air is supplied closer to the room setpoint, less heating energy is needed to condition the room. DV systems provide more versatility as they can also operate in CAV or VAV modes.

Design considerations

In new construction, DV systems are ideal when room configurations allow. Since the air is supplied lower to the floor, diffusers are typically wall mounted, requiring large frontal areas to accommodate adequate ventilation at low velocity. Typically, these can be placed in areas that would otherwise be “unused” (e.g., placing the diffuser directly under the TV set in a patient room). The flow path from heat sources to occupants warrants particular attention to ensure enough conditioned air will come in contact with the occupants before the conditioned air is warmed by window solar gains or other heat sources located in the room.

DV systems can also be an ideal choice for renovated spaces as they can pair with existing overhead mixing systems. Ceiling spaces with low clearances or with little open space, due to utilities and other systems, are especially ideal for DV. If converted from traditional overhead mixing to DV, the same supply runs can also be reused, and the system will benefit from lower duct velocities, due to the lower amount of supply air required. Since the supply air temperature will be different from overhead mixing, the respective control strategy should be revised. The decreased coil cooling load may also lead to revisions to chilled water (CHW) piping as well.

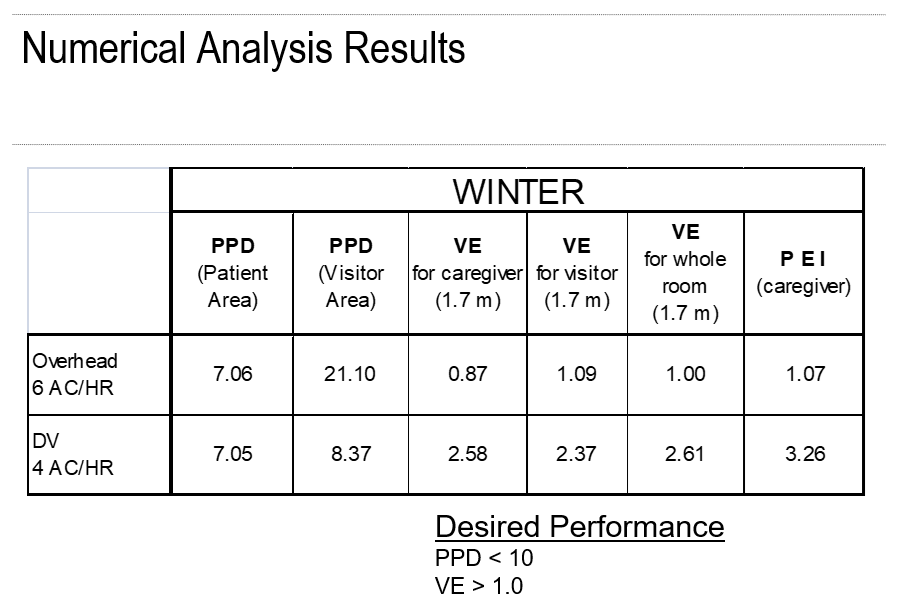

Multiple bodies of evidence indicate that DV helps mitigate the spread of airborne-diseases, including COVID-19. A CFD model comparing the efficacy of DV and traditional mixing revealed the following result:

- “Consequently, if designed properly, displacement ventilation, which encourages vertical stratification and is designed to remove the polluted warm air near the ceiling, seems to be the most effective at reducing the exposure risk. Mixing ventilation distributes the air throughout the space and does not provide any potentially clean zones.”

- By using DV, improved IAQ is provided even at 33% less airflow when compared to overhead mixing systems. By supplying conditioned air directly into the breathing zone, the peak normalized concentration is below 1.0, indicating a lower contaminant concentration throughout. Overhead mixing shows a peak of about 1.4, indicating an area of abnormally high concentration. Although this occurs high in the breathing zone due to buoyancy, it can still be hazardous.

Control strategies

Control strategies are no different from overhead mixing systems and can still be used with VAV terminal units.

DV works best in spaces where heating loads are no more than 15 Btu/h/sf of floor space and sunlight contacts no more than approximately 5% of the room floor area. To improve performance (or where sunlight contact exceeds 5% of floor area), building management system (BMS) controlled automated shading systems can be added.

Best practices

Displacement ventilation is especially suited for high occupancy open spaces with high ceilings (greater than 9 ft). Spaces with high ceilings improve the stratification effect, leading to “taller” areas of cleaner air. A larger proportion of the room’s contaminants and heat will have risen well above the occupied zone.

When air supplied at lower velocities (<40 fpm), the diffusers are much quieter. This makes DV an attractive choice for any space with strict acoustic requirements, such as theaters, patient rooms or some office spaces.

Benefits of a displacement ventilation system include airflow reduction, improved ventilation effectiveness, improved indoor air quality, a reduction in chiller load, a reduction in required equipment size, and most importantly, reduced heating energy.

How does this decarbonize?

In general, displacement ventilation offers appreciable reductions in total site energy requirements and the possibility for reduction in construction materials and cost. From ASHRAE Standard 62.1, the ventilation effectiveness for overhead mixing supply is 1.0, whereas displacement ventilation has a value of 1.2, indicating 20% less airflow required. The supply air temperature is closer to the space temperature, resulting in air heating savings. Typical systems reheat the supply airstream from 55°F up to the required temperature to heat the space, typically at 80°F. DV supplies air around 65°F, resulting in 15°F of air heating (from 65°F to 80°F) versus 25°F (a 40% reduction). Since the ventilation effectiveness is improved, compounded savings for reheat could result in reductions of up to 60% per year of what is typically used for overhead mixing systems.

Lower airflow rate requirements can equate to smaller ducts (if retaining similar sizing criteria). Alternatively, a design with duct sizes based on traditional mixing airflow rates can benefit from lower duct velocities, which leads to less pressure loss through fittings and smaller air handling equipment. Lower duct losses result in decreased fan energy, which can result in 10-20% annual savings in Scope 2 emissions from purchased electricity. Smaller air handling equipment can equate to smaller heating coils, reducing Scope 1 Natural gas emissions by 10-15% annually.

Implementation

Barriers: Culture

Most designers default to traditional overhead mixing systems as they are more commonly understood and perceived to be more “predictable” due to the variety of building load programs featuring the system (i.e. path of least resistance). Commercially available load calculation software featuring a DV option is still relatively new (newly added to Trace3D) and expensive to license. Thus, engineers must then create their own calculation spreadsheets, which are not easily standardized.

Barriers: Technical

For effective cooling with DV, floor area exposed to direct sunlight must be limited to 5%, which can necessitate the usage of BMS-controlled shading devices. However, for most buildings prioritizing energy savings, BMS-controlled shading is standard. Since the diffusers are typically low-wall located, additional coordination with the architect is advised. The diffusers should blend into the interior design. Additional heating systems must also be applied in spaces. Due to the thermal plume effect, cooling capacity is diminished where low heat gain is applied and in areas with rapid load change such as ORs and data centers.

As mentioned before, additional design coordination is advised to ensure an integrated design. The low-wall supply may interfere with architectural elements; however, a wide array of specialty diffusers (to minimize aesthetic impact) exist.

Displacement ventilation diffusers are typically more expensive than conventional mixing diffusers; however, this accounts for a small portion of the total cost of an HVAC system. Any additional cost from diffusers will be quickly rectified in cooling energy savings. Diffuser types are diverse and can supply air from floor plenums, wall diffusers, and waterfall diffusers. In general, DV systems can be 10-20% cheaper to operate (compared to overhead mixing systems) due to lower energy costs and equipment maintenance.

Strategy

As early as possible in the design process, architectural coordination should be conducted to ensure diffusers are placed for optimal aesthetic and functionality (i.e., efficiently conditioning the space). Similarly, other trades should also be notified early to assess respective implications.

Select an MEP engineering design firm with experience using DV. Given this type of ventilation system is still fairly new, at least in the U.S., an experienced firm will be more inclined to understand the critical nuances and the respective coordination (and conversations) needed.

Schematically draft full-size ductwork in order to make diffuser setup work. This will set the space aside, apart from other trades.

Figure 2. Example of Architectural Coordination for Displacement Diffuser

Financial analysis and business case

For new construction, first costs of equipment and air distribution can be less, however architectural cost impacts should include the widened walls and the footprint of the DV units themselves. Operational savings can be simple to analyze, where one would compare the cost savings from lower airflows and higher cooling supply air temperatures. First cost analysis comparing DV and traditional equipment and operating costs is an effective method of creating an economic case.

In an existing building, the cost premium will be pretty high. Larger wall spacing is required, and may necessitate room remodeling. Revisions to SAT control will also be required. If reusing existing AHU’s, the decreased cooling requirement may necessitate smaller cooling coils and/or control valves, or rebalancing of the chilled water system. However, the cooling energy savings will cover these costs over the course of 2-5 years depending on the scale of the reconfiguration.

Case Study: LPCH

Lucile Packard Children’s Hospital (LPCH). See 2020 ASHRAE Technology Award Case Study. The energy use intensity (EUI) was determined to be 179 kBtu/sf/year, as compared to a value of 305 for an equivalent building using ASHRAE 90.1-2007 baseline systems and building components. From a Measurement and Verification report completed after project commissioning, the actual EUI for the building was 167 kBtu/sf/year. The resulting system is using 45% less total energy than a baseline system.

Comments

John Doe

8 seconds ago

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quisquam, voluptatum. Lorem ipsum dolor sit amet consectetur adipisicing elit. Quisquam, voluptatum.

John Doe

18 seconds ago

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quisquam, voluptatum. Lorem ipsum dolor sit amet consectetur adipisicing elit. Quisquam, voluptatum.